Our services

We’ve refined our specialism and developed pioneering offerings in both the public and private sectors. Together, we are committed to ongoing learning, science, and innovation so that our clients always remain at the forefront of industry developments.

Explore how our services can assist you and your project.

Façade Structural Engineering

We embrace the materiality of facades and can complete tailored analysis across a range of applications. The following are our in-house capabilities and specialisms.

We work with the following materials:

- Stone

- Concrete

- Metals

- Glass

- Timber

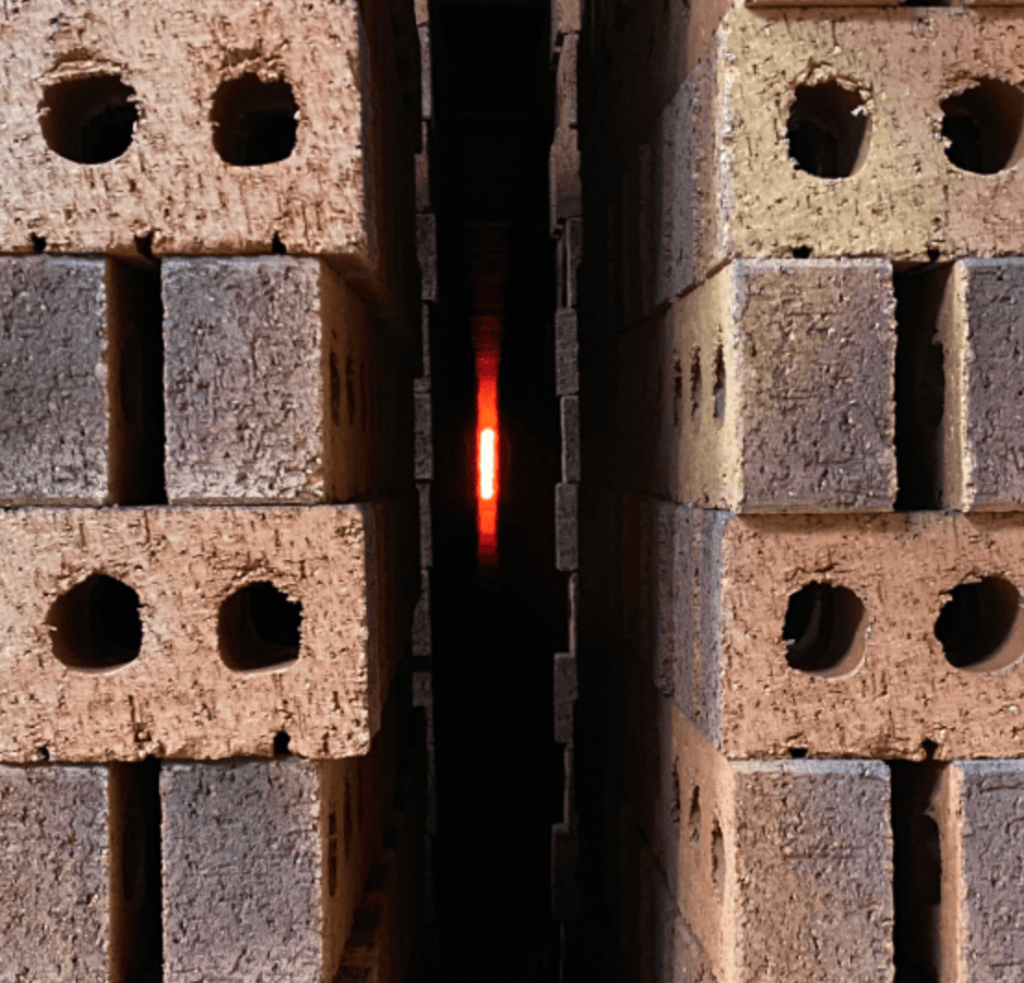

- Clays/Shale

Façade Thermal Engineering

We specialise thermal engineering services for facades. Our expertise lies in optimising thermal performance, improving energy efficiency, and enhancing sustainability in building exteriors. Whether you’re an architect, developer, or facility manager, we provide tailored solutions to meet your specific needs.

We offer the following:

- U-value assessment and optimisation

- Interstitial Condensation assessment

- Surface Condensation analysis

- Custom climate analysis (Global)

- Chi Loss analysis

- 2D Steady state analysis – U-value + Dew point

- 3D Thermal Analysis

- Psi loss calculation

- Glass thermal fracture analysis

Performance Specifications

Fortis provide tailored performance specifications which adhere to regional standards & codes, industry guidance and best practice. We have also designed our specification writing to account for sustainability through embodied carbon awareness. Our specifications are coordinated with our design and engineering stages which align with Golden Thread reporting.

With an appreciate that industry standards are centric to region and that they are sometimes shared across countries, we are accustomed to auditing prescriptive performance specifications as well as authoring on behalf of our clients. We can create bespoke specifications which control the procedures, define roles and ensure material baseline performance are adhered to.

Advisory & Expert Witness

We offer independent specialist advisory consultancy for litigation where assistance in complex claims are required.

We also provide Expert Witness services in accordance with Civil Procedure Rules Part 35 (CPR-35) on behalf of the courts.

We have a track record of assisting in legal matters and are accustomed to regional proceedings.

Site Surveying & Monitoring

Our site operatives are Health & Safety trained via accredited training schemes but also our retain a specialist Health & Safety Advisor.

We will attend and monitor sites on behalf of Client, Main Contractors and Contractors.

We help by highlighting the critical elements that potential influence insurances and building longevity and performance. We also pride ourselves on an ability to be practical and offer informed judgement on design that from time to time needs to be altered or adapted on live sites and help evidence through engineering, that changes can positively contribute to construction.

Logistics & Procurement

The export and import of high-value façade fabric is one of the definitive processes which determine the success of projects which are dependent on the delivery of secured assets.

Fortis have a deep procurement route knowledge which covers land, sea, rail and air transit. We help our clients with:

- Live asset tracking including bill of lading and material certification monitoring

- Independent review of factory output and shipping manifests to validate capacity and production timing

- Custom packaging and protection design

- Regional and local independent monitoring of:

- Extraction

- Manufacture

- Fabrication & Assembly

- Custom Inspection Test Plans (ITPs) for Quality Assurance & Quality Control

- Sustainability Practices: Emphasising sustainability in logistics practices, such as optimising routes to reduce carbon emissions and recommending eco-friendly materials, aligning with environmental goals, from transit method to packaging

- Security Measures: Review of storage facilities insurances and deterrent facilities and general management

- Risk Management: Implementing proactive risk management strategies to identify potential delays or problems before they impact the project, thereby minimising downtime and cost overruns by reviewing available contingency logistics.

Façade Access & Maintenance

Property remains one of the safer investment markets. The ability to maintain assets reduces the dilution of valuations, Fortis prescribe tailored access and maintenance strategies to ensure safety and longevity in fabric management.

Fortis offer the following:

- Evidence of hierarchical approach to access strategies in accordance with CDM responsibilities and prevailing standards and best practice guidance whilst providing cost considerations which are appropriate.

- Access device engineering and integration with façade structure including accounting for imparted loads.

- Comparative analysis of varied access designs through cyclic modelling to provide time and budget considerations for the costing teams.

- Atmospheric analysis through our unique BIOME offering we can determine the optimum periods of maintenance and general cleaning, we consider:

- Materiality

- Specific regions through meteorological profiling of exact site location

- Seasonal influences: drying potential, surface asperity, building shading, frequency and duration of exposure

- Façade fenestration and relief

- Replacement strategies for all materials including plant, operative requirements and sequential planning.

Building Physics

Using industry recognised software we offer an ability to gain insight into the way in which building fabric interacts with the world we live in. This is not only the atmospheric process that drive our planetary weather systems but also the way in which we occupy buildings.

Our specialist teams can provide hydrothermal analysis of construction interfacing whether it be new build or existing. We provide steady-state analysis and dynamic simulation to assess the following:

- Design to regional codes

- Mould growth propagation

- Mould risk analysis

- Identify potential ecological species

- Drying potential

- Interstitial condensation

- Surface condensation

Fortis do not rely solely on predetermined climatic data sets provided by others which are often built-in or plug-in to software. We use a combination of GIS and atmospheric data specific to your region from approved data loggers and weather stations to accurately represent conditions buildings experience, as opposed to general region. This can positively influence sustainability by reducing material needs but also highlight areas which require resilience design, and therefore increases longevity of building materials which respond and accommodate the environment intended for.

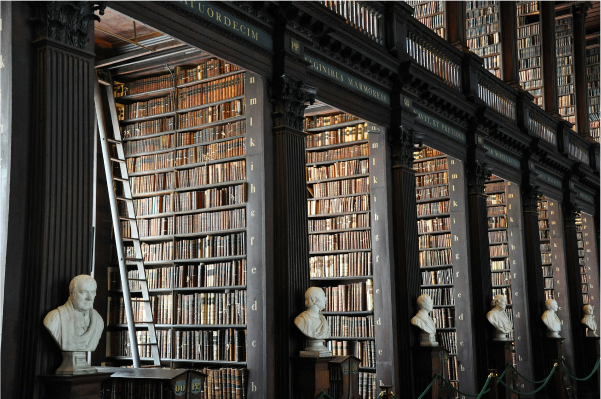

Refurbishment & Preservation

Fortis provide detail existing condition surveys which highlight scopes of works required to achieve client aspirations.

Fortis have helped lead industry within the last 5 years for combining understanding of old structures, their construction methodologies and building materials with the need for modern day adaptation. Part of the challenge we face is the interfacing of modern technologies with structures that have once operated not only with traditional mechanical and electrical design, but the very fabric and the construction differs such that it can hinder and even restrict the introduction of modern materials.

Having an appreciation of where we have come from is essential in understand where we’re going. Fortis pride our historic knowledge on different construction eras through to significant cultural heritage works. It’s this knowledge, combined with our multi-disciplinary approach to façade engineering that allows for a balanced assessments that are sympathetic to each project.

Where validation of existing building material requires evidencing extension of service life, we coordinate on behalf of the client using prevailing regional standards with laboratory or on-site testing where applicable.

Innovation & Research & Development

Fortis can help companies with façade product development through completing engineering analysis and coordinating independent testing.

We partner with specialist patent advisors who help clients with Intellectual Property applications whilst providing innovation through either reverse engineering or composite design. We work with clients to identifying unique product properties that qualify as genuine innovation that help drive industry forward.

Fortis work across engineering and environmental disciplines to help answer challenging questions that can not ordinarily be answered by traditional design and engineering. We created BIOME a scientific division to amalgamate environmental sciences and engineering disciplines so that building envelope design can be accountable by innovating the approach through detailed atmospheric and regional environmental profiling to reduce risk profile for building insurance.

Resilience Design & Engineering

Building envelopes, through design can be made to serve several functions either at the same time or when required. This design ensures materials that typically are a focus of aesthetics, carry inherent embodied carbon and are essentially only passengers attached to the side of structures are consistently working during the design and service life period.

Fortis have a track record of showing design teams how we can create responsive design to occupancy and adapt to seasonal climates but also climate profiles which perhaps have not reach us yet. This creates a façade that is not appearance centric but one which has longevity and ability to recover or manage permutations experienced across the fabric; a resilience façade.

We combine historic meteorological data, live climatic trends and project climates forwards to qualify engineering judgement so that specific facade responses are realised at the start of design processes and can be budgeted for. This body of works will always contribute to sustainable accreditation and has preservation at the heart of the process.

Forensics & Investigations

Fortis are independent specialists who have experience across industry standard and non-standard façade systems. Our experience comprises of first-hand design, engineering, manufacturing, fabrication and installation this places us in a unique position to audit others works and investigate latent defects or quality of workmanship.

We use a multitude of techniques which we can use to assist in reporting, such as but not limited to; coordination of laboratory test analysis, use of on-site specialist equipment, statistical analysis, historical referencing and context reporting, and other trade techniques depending on the objective. Having these facets allows us to tailor our approach to almost all building related issues and get to the causation in a timely manner whilst providing rationale for record keeping and peer review.

Incident Response

The following are causation elements in relation to facades:

- Duress from climatic force and associated debris

- Latent defects from inadequacy in design and/or workmanship

- Water damage through façade fabrics to internal finishes

Key factors which govern are:

- Life Safety

- Damage to Property

- Fabric performance

Fortis have a dedicated team that support first responders to façade fabric failures. We assist with the following:

- Short notice availability

- Ascertaining project specific information

- For meteorological events; Historic data analysis and event classification

- Observation and defect recording

- Assist with the management of site

- Provide initial remedial solutions

- Provide final engineered solutions

- Provide specialist advice to loss adjustors and insurance

- Assist with the validation of remedial solutions provided by others

Building Environmental Assessment Support

We can support the coordination of accredited assessments for certification for the following:

BREEAM (UK)

BREEAM is the world’s foremost science-based framework for validating and certifying a more sustainable built environment.

- Management

- Health and Wellbeing

- Energy

- Materials

- Waste

- Pollution

- Innovation

Green Star (AUS)

Established by the Green Building Council of Australia in 2003, Green Star is a globally recognised rating system that defines benchmarks for creating healthy, resilient, and sustainable buildings and spaces.- Energy

- Materials

- Indoor Environment Quality (IEQ)

- Emissions

- Management

- Innovation

- Social Sustainability

LEED (US)

The US Green Building Council drives and scales the transformation of the built environment to reduce climate impacts while improving the well-being of people, the environment, and communities globally.- Integrative Process, Planning, and Assessments

- Energy and Atmosphere

- Materials and Resources

- Indoor Environmental Quality

- Project Priorities and Innovation

Historic Royal Palaces have commissioned several projects in relation to the maintenance and preservation of The Tower. The site is one which requires the definition of care, considered approach and technical competency these are unconditional. Fortis have been nothing shy of exceptional in displaying the respect the structure requires. Whilst working with them closely they were also humble about being involved with our projects and this was refreshing as it allowed for concentration and meaningful discussions about the works in hand. We will always welcome Fortis to help with our sites and thank them for the dedication they have shown to date.

I am a Commercial Manager working for Mount Anvil Limited, a residential developer based in Central London. We have worked successfully with Fortis Facades Limited during 2023 – 2024 on façade related issues. We have found them to be extremely knowledgeable and managed to explain to audiences at all levels of technical understanding. Detailed technical reports on the subject matter have been followed up with presentation in layman’s terms. We have no hesitation in recommending Fortis Facades Limited and they will be tendering for our future schemes as façade consultant.

I have had the good fortune to work with David since 2018. While both of us were at Inhabit I relied on him daily and more recently (at Mace Facades) we continued to work on projects together.

David’s flexibility and thirst for knowledge coupled with his conscientious manner meant that I could always rely on him to do the best for our clients from a technical, budget and practical perspective. I hope to work again with him and look forward to seeing his new venture and team grow over the coming years.”

“I worked with David on a large mixed-use project between 2017 and 2021 when he provided technical advice to one of my clients on some cladding defects.

As a technical expert, David is impressive. His technical knowledge and passion for the subject make him stand out. He has a rare combination of qualities which make him a pleasure to work with and I would not hesitate to recommend him. I look forward to future opportunities to work with him.”