It is fundamental to understand, or at least appreciate, where we have come from if we are going to progress.

This article is a very brief snapshot of one of London’s prestigious glass processors and installers that contributed to the city’s reflectiveness. The timeline is incomplete, so apologies in advance, there was just so much material and I tried to be efficient with aspects that told the story.

In the beginning

Where and who were supplying processed glass in London at the turn of the 20th century? Coincidentally, I discovered only recently that my past is inherently linked to façade construction, one which spans generations and is connected, albeit in a small way, to this question. This article is about some of the uncelebrated origins of glazing and the triumphs that one company endured.

On our small island where so much industry has birthed and sadly fallen, for those that have an avid interest in glass and its history and those that are eager to further their knowledge, you may enjoy learning that during the 19th and 20th century James Clark & Eaton Limited (JCE) was one of London’s established glass processing merchants.

1855 saw JCE’s first year of trading and for some, perhaps irrelevant, context but interesting nonetheless, in the same year the First Sioux War: Battle Of Ash Hollow was fought in the United States, Australia was granted self-governing status and David Livingstone discovered Victoria Falls, all whilst broad and crown glass technology was being processed for our streets of London and other parts of Great Britain.

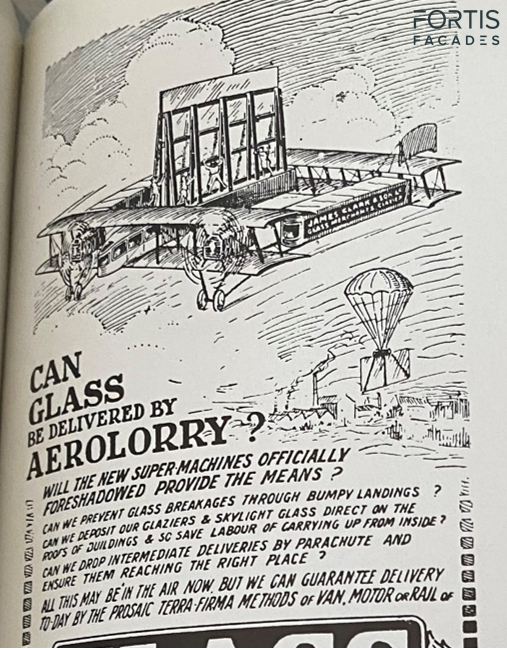

Evolution of transport

The business originally delivered glass via three flat, horse-drawn carts. This is particularly interesting as most will imagine the vertical A-frames we have today. On the contrary, the glass was carried horizontally (in its weakest position). For distances not local, the deliveries were made to the local train stations for transport, but still laid flat. Glass was reported broken upon delivery… often. One of the original premises of note were the arches in Scoresby Street. This is where the railway arches housed the horses too.